In an article published in the Harvard Business Review in July/August 1999, the leadership guru and the author of the best-selling book Good to Great, Jim Collins, wrote about something he termed as catalytic mechanisms. Catalytic mechanisms are mechanisms used in organizations to create a compelling alignment between a business and its strategy to differentiate itself.

According to a study done by McKinsey, 73% of transformation projects fail. 1 in 5 projects fail so badly that they threaten the existence of the business. Change management has failed and every failure is accompanied by the usual explanations: lack of communication, people resistance, poor implementation, etc. So the question is why has change management failed and what if any is the alternative?

According to a study done by McKinsey, 73% of transformation projects fail. 1 in 5 projects fail so badly that they threaten the existence of the business. Change management has failed and every failure is accompanied by the usual explanations: lack of communication, people resistance, poor implementation, etc. So the question is why has change management failed and what if any is the alternative? Lean is about streamlining processes and Six Sigma is about reducing defects. The Lean Six Sigma methodology is therefore a way of accelerating Six Sigma by streamlining the process while reducing defects. Lean Six Sigma is applicable to all kinds of organizations including not-for-profit organizations and can produce remarkable benefits in productivity, revenue, profitability as well as customer satisfaction. Here are some key principles of Lean Six Sigma…

Lean is about streamlining processes and Six Sigma is about reducing defects. The Lean Six Sigma methodology is therefore a way of accelerating Six Sigma by streamlining the process while reducing defects. Lean Six Sigma is applicable to all kinds of organizations including not-for-profit organizations and can produce remarkable benefits in productivity, revenue, profitability as well as customer satisfaction. Here are some key principles of Lean Six Sigma… Why do we hate change? The answer can be found in human evolution. Since millions of years ago, the human brain perceives strangeness (or strangers for that matter) as a sign of danger or even a life-threatening event. Our brains are hard-wired to react negatively to and to resist change. Organizations face the same challenges of inevitable resistance to change. According to one study by the Center for Creative Leadership, 75% of change initiatives fail because of this resistance. ..

Why do we hate change? The answer can be found in human evolution. Since millions of years ago, the human brain perceives strangeness (or strangers for that matter) as a sign of danger or even a life-threatening event. Our brains are hard-wired to react negatively to and to resist change. Organizations face the same challenges of inevitable resistance to change. According to one study by the Center for Creative Leadership, 75% of change initiatives fail because of this resistance. ..  Based on a web article entitled “The Future of Management is Teal”.

Based on a web article entitled “The Future of Management is Teal”. Lean management began as an effort at Toyota to reduce time for a manufacturing process and thus reduce in-process inventory. This became known as just-in-time inventory management. The result was less warehouse space, fewer forklifts, less workshop space, etc. Once the flow of work can be free of interruption and unnecessary repeat work, waste is eliminated. Lean is therefore the elimination of waste. But, more importantly, lean is continuous improvement in all work processes…

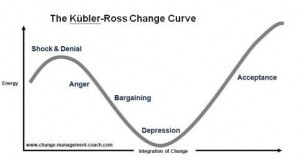

Lean management began as an effort at Toyota to reduce time for a manufacturing process and thus reduce in-process inventory. This became known as just-in-time inventory management. The result was less warehouse space, fewer forklifts, less workshop space, etc. Once the flow of work can be free of interruption and unnecessary repeat work, waste is eliminated. Lean is therefore the elimination of waste. But, more importantly, lean is continuous improvement in all work processes… Any kind of change involves the loss of something: status quo, possessions, relationships, etc. The 5-Stage model suggested by Elisabeth Kubler-Ross in a book related to loss of life (an extreme form of loss) has been also used to explain how people react to change…

Any kind of change involves the loss of something: status quo, possessions, relationships, etc. The 5-Stage model suggested by Elisabeth Kubler-Ross in a book related to loss of life (an extreme form of loss) has been also used to explain how people react to change…

Recent Comments